Hayne Alloy 188 Gh188 / Gh5188 / Solid Solution Strengthening Cobalt

Description

Basic Info.

| Model NO. | Hayne 188 |

| Technique | Cold Treatment |

| Density | 8.4G/Cm |

| Manufacturing Process | Solution Treatment |

| Shape | Wrie, Pipe, Bar, Strip, Plate |

| Surface | Bright/Black |

| Melting Point | 1290-1350c |

| Transport Package | Carton or Wooden Case |

| Specification | GB, AISI, ASTM, DIN, EN, SUS, UNS |

| Trademark | DLX |

| Origin | Changzhou, Jiangsu, China |

| HS Code | 7506200000 |

| Production Capacity | 1000kg Per Week |

Product Description

Hayne Alloy 188 GH188 / GH5188 / Solid Solution Strengthening Cobalt-Based Superalloy Rod Bar

GH5188 solution-strengthening cobalt-based superalloy, adding 14% tungsten solid solution strengthening, makes the alloy have excellent high-temperature thermal strength, adding high content of chromium and trace lanthanum, so that the alloy has good high-temperature oxidation resistance, and has Satisfactory forming, welding and other process properties, suitable for manufacturing aero-engine parts that require high strength below 980°C and anti-oxidation below 1100°C. It can also be used on aerospace engines and space shuttles. It can produce and supply various deformed products, such as sheet, medium plate, strip, bar, forging, wire and precision casting.

1.1 GH5188 (GH188) material grade GH5188 (GH188).

1.2 GH5188 (GH188) similar grades Haynes Alloy No.188 (HA188), UNSR30188 (USA), KCN22W (France).

UNS R30188

Chemical composition

| % | Co | Ni | Cr | W | Fe | C | Mn | Si | P | S | La | B |

| min | balance | 20.0 | 20.0 | 13.0 | 0.05 | 0.20 | 0.02 | |||||

max | 24.0 | 24.0 | 16.0 | 3.0 | 0.15 | 1.25 | 0.50 | 0.020 | 0.015 | 0.12 | 0.015 |

Physical properties

| Density | 8.98 g/cm3 |

| Melting range | 1315-1410ºC |

Our company Principle is " Quality first, Customer first".

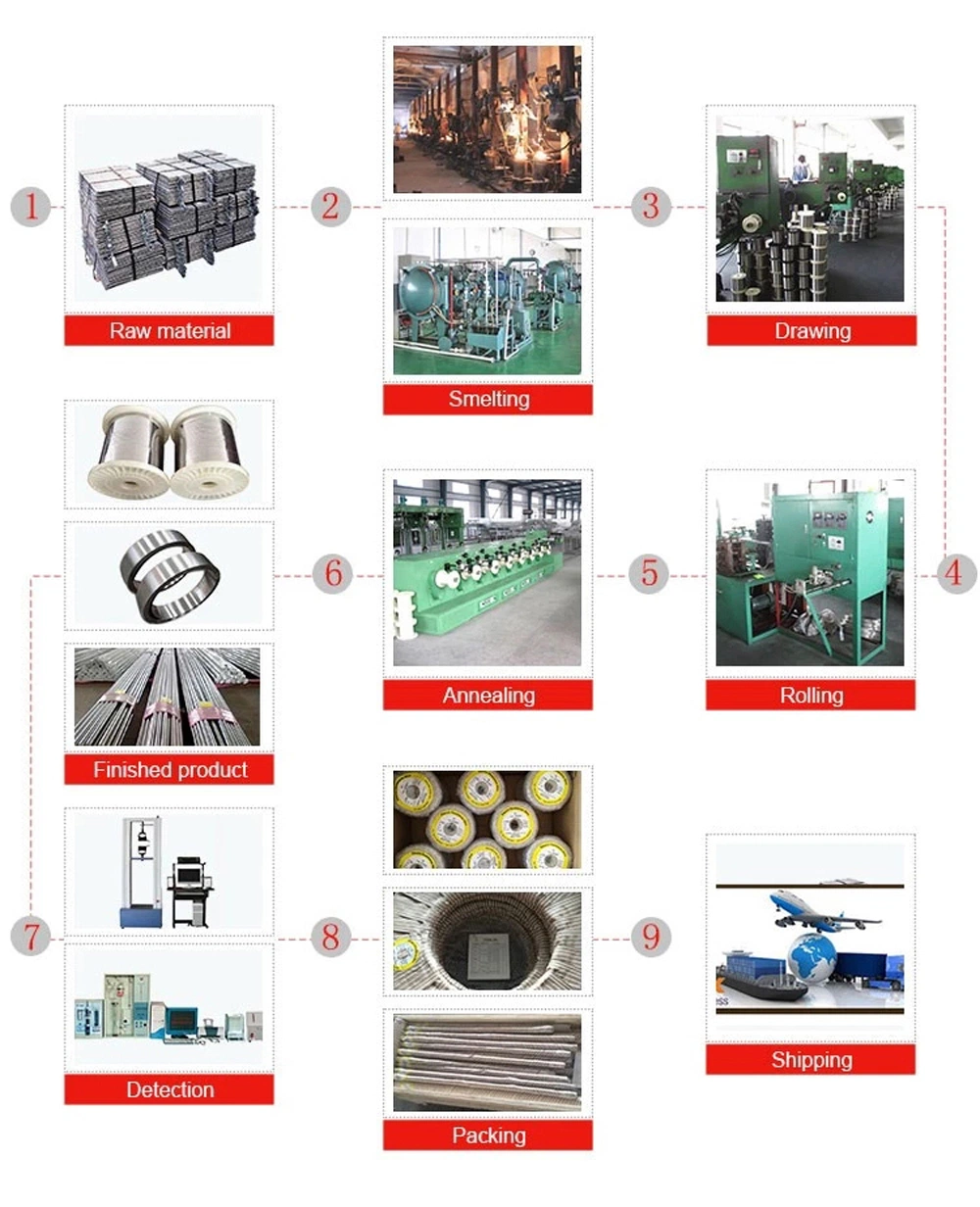

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples.2, We can provide the products within a week after payment.3, Wecan provide sample of the products customer need.4, We always insist on "Quality first, Customer first" as our business philosophy.

Packaging & ShippingQuestion: Are you a trading company or manufacturer?

Answer: We're manufacturer.

Question: could we visit your factory?Answer: Sure, factory visit is warmly welcome.

Our Contact