Dx51d+Zf Dx55D+Zf Dx56D+Zf Dx57D+Zf Low Carbon Steels for Cold Forming Automobile Steel

Low carbon steels provide a number of advantages when it comes to cold forming applications. These materials are known f

Description

Basic Info.

| Model NO. | Dx51d+Zf |

| Application | Automotive Plate |

| Edge | Other |

| Stock | Stock |

| Remember The Way | Weighing |

| Material Proof | Factory Material Sheet |

| Pre-Sales Consultation | 1V1 Docking |

| Processing Services | Slitting Slitting Cross Cutting Pendulum Shearing |

| Pre-Sale | One-on-One Customer Service |

| Transport Package | Export Standard Packaging or on Request |

| Specification | customizable |

| Trademark | Baosteel |

| Origin | China |

Product Description

Low carbon steels provide a number of advantages when it comes to cold forming applications. These materials are known for their high strength-to-weight ratio and ductility, making them an ideal choice in situations where weight is a factor and forming shapes is essential. Furthermore, there's less likelihood of cracking or breaking during the process which makes them suitable for everything from tubing and pipes to wire products and automotive parts.Solucky steel Limited is a third-party supply chain service enterprise focusing on materials for automobiles, high-end household appliances, as well as material processing and storage. Its headquarters and warehouse base are set up in Shanghai BaoShan, and has branches all over the country, 20+ subsidiary companies,including Foshan, Guangdong, Chongqing, Wuxi, etcz. Chemical composition and Mechanical propertiesSteel grade | Chemical composition | ||||||

% by mass | |||||||

max. | |||||||

C | Si | Mn | P | S | Ti | ||

DX51D | 0.18 | 0.5 | 1.2 | 0.12 | 0.45 | 0.3 | |

DX52D | 0.12 | 0.5 | 0.6 | 0.1 | 0.45 | 0.3 | |

DX53D | 0.12 | 0.5 | 0.6 | 0.1 | 0.45 | 0.3 | |

DX54D | 0.12 | 0.5 | 0.6 | 0.1 | 0.45 | 0.3 | |

DX55D | 0.12 | 0.5 | 0.6 | 0.1 | 0.45 | 0.3 | |

DX56D | 0.12 | 0.5 | 0.6 | 0.1 | 0.45 | 0.3 | |

DX57D | 0.12 | 0.5 | 0.6 | 0.1 | 0.45 | 0.3 | |

Steel grade | Symbols for the types of available | ||||||||||

Yield | Tensile | Elongation | |||||||||

coatings | strength | strength | % | ||||||||

MPa | MPa | min | |||||||||

DX51D | +ZF | - | 270 to 500 | 22 | |||||||

DX52D | +ZF | 140 to 300 | 270 to 420 | 26 | |||||||

DX53D | +ZF | 140 to 260 | 270 to 380 | 30 | |||||||

DX54D | +ZF | 120 to 220 | 260 to 350 | 34 | |||||||

DX56D | +ZF | 120 to 180 | 260 to 350 | 37 | |||||||

DX57D | +ZF | 120 to 170 | 260 to 350 | 39 | |||||||

Main Products

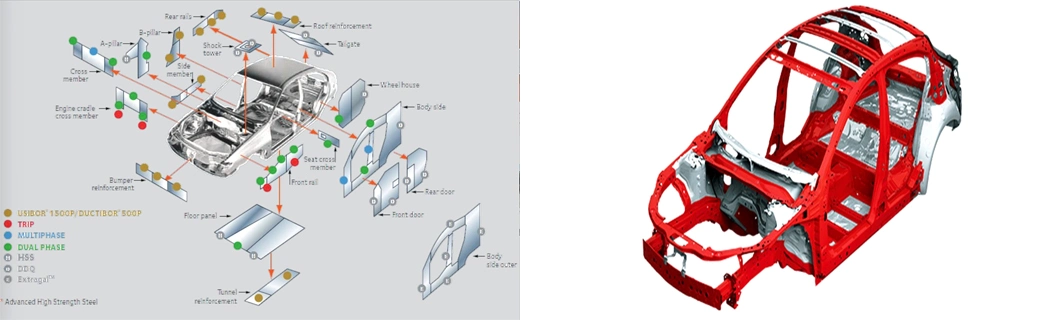

Product Application

Machines & ProcessingPacking & Delivery & logisticsWhy Choose Us

FAQ

1.Where is your factory?Our head office and warehouse located in Shanghai--the biggest steel making center of China 2.How long is your delivery time? Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity. 3.What about the MOQ? MOQ only 200KG,include coils and sheets 4. How long is your lead time? In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur. 5.How's your product quality? We only sell mid to high end steel materials,100% quality guarantee and cost-effective. 6.What are your terms of payment? You can make the payment to our bank account,T/T, 30% deposit in advance, 70% balance against the copy of B/L. 7.How many countries you already exported to? We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana,somalia and other African countries.Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble. 8.What are the certifications for your products? We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

Our Contact

Send now