Customized Steel for Forging Dies 1.2343 X38crmov51 H11 SKD6 1.2344 X40crmov51 H13 SKD61 High Speed Tool Steel Round Bar

Description

Basic Info.

| Model NO. | 1.2343 X38CrMoV51 H11 SKD6 1.2344 X40CrMoV51 H1 |

| Application | Tool Steel Bar |

| Testing | Physical Properties, Flaw Detection |

| Delivery Date | 7-20days |

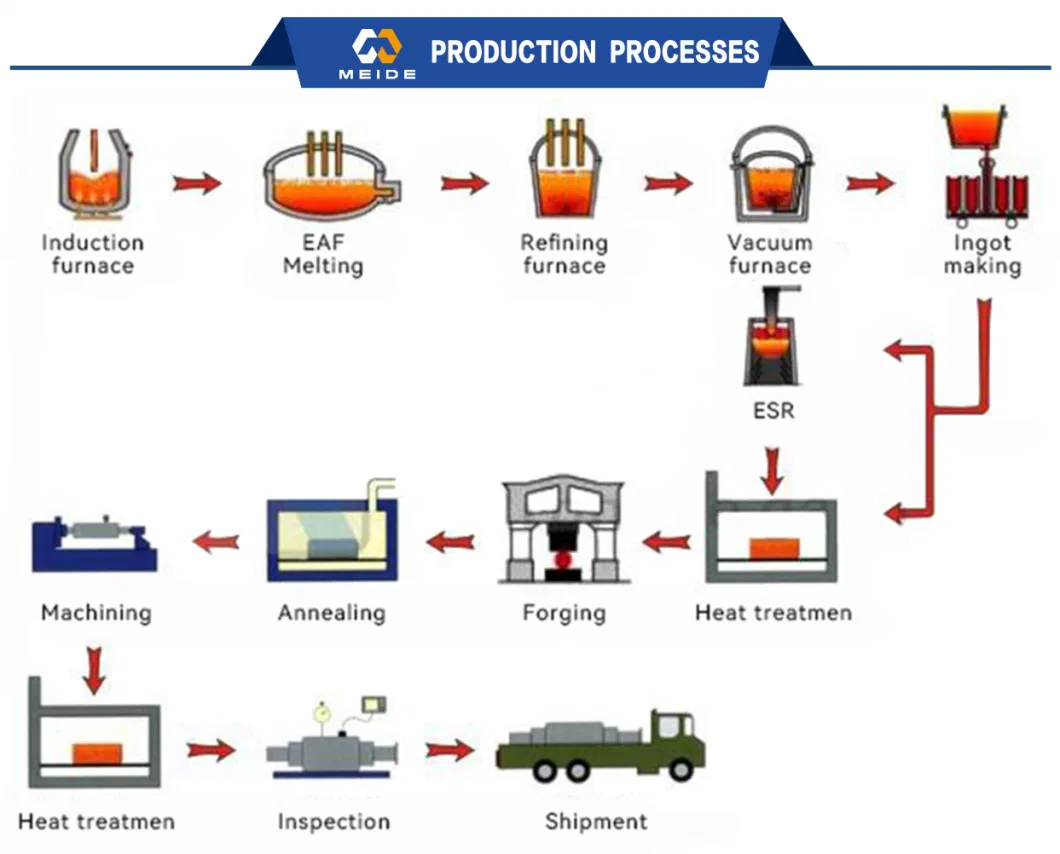

| Heat Treatment | Annealing/Normalizing/Q+T |

| Delivery Conditions | Forging/Hot Rolling/Cold Drawing |

| Transport Package | Standard Seaworthy Export Packaging or as Required |

| Specification | 3000-9000mm |

| Trademark | meide |

| Origin | Shandong, China |

| HS Code | 84802000 |

| Production Capacity | 1000 Ton/Month |

Product Description

| Steel Grade | C | Si | Mn | Cr | Mo | V | P | S |

| H10/SKD7/1.2365/4Cr5Mo2V | 0.35-0.45 | 0.8-1.25 | 0.2-0.7 | 3-3.75 | 2-3 | 0.25-0.75 | ≤0.03 | ≤0.03 |

| 1.2367/4Cr5Mo3V | 0.35-0.4 | 0.3-0.5 | 0.3-0.5 | 4.8-5.2 | 2.7-3.2 | 0.4-0.6 | ≤0.03 | ≤0.02 |

| H11/SKD6/1.2343/4Cr5MoSiV | 0.33-0.43 | 0.80-125 | 0.20-0.60 | 4.75-5.50 | 1.10-1.60 | 0.30-0.60 | ≤0.03 | ≤0.03 |

| H12/SKD62/X35CrWMoV5/1.2605/4Cr5MoWVSi | ||||||||

| H13/SKD61/1.2344/4Cr5MoSiV1 | 0.32-0.45 | 0.08-1.20 | 0.20-0.50 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 | ≤0.03 | ≤0.03 |

| H21/SKD6/1.2531/SKD5/3Cr2Mo8V | 0.32-0.42 | 0 .8-1.2 | ≤0.5 | ≤0.03 | ≤0.02 | 0.3-0.5 | ≤0.03 | ≤0.02 |

| 4CrNi4Mo/T23504/SKT6/45NiCrMo16/1.2767 | 0.4-0.5 | 0.1-0.4 | 0.2-0.5 | 1.2-1.5 | 0.15-0.35 | - | ≤0.03 | ≤0.03 |

| 3Cr2W8V | 0.26-0.36 | 0.15-0.50 | 0.15-0.40 | 3.00-3.75 | - | 0.30-0.60 | ≤0.030 | ≤0.030 |

| P20+Ni/SKD6/1.2738/3Cr2NiMo | 0.32-0.40 | 0.20-0.40 | 1.10-1.50 | 1.70-2.00 | 0.25-0.40 | - | ≤0.030 | ≤0.030 |

| 3Cr2Mo | 0.28-0.40 | 0.28-0.80 | 0.610-1.00 | 1.40-2.00 | 0.30-0.55 | - | ≤0.030 | ≤0.030 |

| SKD11/Cr12Mo1V/D12/D11 | 1.4-1.6 | ≤0.40 | ≤0.60 | 11.0-13.0 | 0.80-1.20 | 0.20-0 .50 | ≤0.030 | ≤0.030 |

| Cr12Mo1V1/D2/1.2379/ Cr12Mo1V1 | 1.40-1.60 | ≤0.60 | ≤0.60 | 11.00-13.00 | 0.70-1.20 | 0.5-1.10 | ≤0.030 | ≤0.030 |

| Cr12/D3/SKD1/1.2080 | 1.9-2.2 | 0.1-0.6 | 0.2-0.6 | 11.00-13.00 | - | -- | ≤0.030 | ≤0.030 |

| 1.2363/A2/SKD12/Cr5Mo1V | 0.95-1.05 | 0.10-0.40 | 0.40-0.80 | 4.80-5.50 | 0.90-1.20 | 0.15-0.35 | ≤0.003 | ≤0.003 |

| 5Cr4Mo3SiMnVA1/T23364 | 0.35-0.45 | 0.8-1.1 | 0.8-1.1 | 1.3-1.5 | 0.4-0.6 | 0.2-0.4 | ≤0.030 | ≤0.030 |

| 4CrMnSiMoV/T23364 | 0.35-0.45 | 0.8-1.1 | 0.8-1.1 | 1.3-1.5 | 0.4-0.6 | 0.2-0.4 | ≤0.030 | ≤0.030 |

| SCM440/EN19 /4140/ 42CrMo4 | 0.38-0.43 | 0.15-0.35 | 0.75-1 | 0.8-1.1 | 0.15-0.25 | - | ≤0.035 | ≤0.04 |

| 1025/1026/26Mn5 | 0.22-1.1 | 0.2-0.35 | 0.3-0.4 | - | - | - | ≤0.025 | ≤0.025 |

| Standard | AISI EN DIN GB JIS ASTM |

| Technique | Hot Rolled/ Forged |

| Alloy Or Not | Is Alloy |

Processing | Heat treatment: soft annealing, normalising, isothermal, spheroidising and stress relieving treatments, quenching and tempering Peeling |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Delivery Time | 8-14days |

| Product Name | Alloy Steel Rod |

| Length | 1-12m |

| Technology | Hot Rolled, Hot Forge, Cold Drawn |

| Process | Forging+Machining(if Need)+surface Treatment |

| MOQ | 1 Ton |

| Diameter | 6mm-800mm |

| Shape | Round. Square. Rectangular |

(1).High temperature strength and good toughness.(2) Good wear resistance.(3) High thermal stability.(4) Excellent thermal fatigue resistance.(5) High hardenability.(6) Good thermal conductivity.(7) Good forming process performance.

Hot working die steel is mainly used to manufacture dies for pressure processing of workpieces under high temperature. Such as: hot forging die, hot extrusion die, die casting die, hot upsetting die, etc. Commonly used hot work die steels include: alloy die steels with medium and high carbon content and added with Cr, W, Mo, V and other alloy elements; Hot work die steel with special requirements is sometimes made of high alloy austenitic heat resistant die steel.

Quality improvement

1. By using the modification effect of Ca, rare earth and other trace elements on inclusions, the structural morphology and physical properties of inclusions in steel can be changed, and the inclusions in steel can be spheroidized and refined, so as to improve the mechanical properties of steel.

2. The high temperature diffusion heat treatment of steel ingot can improve the composition nonuniformity of steel ingot, thus improving the transverse performance of steel.

3. In terms of hot working, repeated upsetting and multi-directional rolling of steel ingots can reduce the level of carbide segregation in steel and improve the anisotropy of steel.

4. The purity of steel has a great impact on the isotropic properties of die steel. The use of secondary refining technology (including vacuum refining, ESR and ladle powder spraying) can improve the purity of steel, especially reduce the content of harmful impurities in steel, which is very beneficial to improve the performance

Packaging | 1. by bundles, each bundle weight under 3 tons, for small outer diameter steel bars, each bundle with 4 - 8 steel strips. 2. after making by bundle, covered with Polyethylene waterproof cloth. 3. make black paints painting on each bar, then make bundles |

| 20 feet container contains dimension | Length under 6000mm |

| 40 feet container contains dimension | Length under 12000mm |

| By bulk vessel | Freight charge is low by bulk cargo, and large heavy sizes can not be loaded into containers can shipping by bulk cargo |

FAQ

1. Who are we?

Our headquarter is located in Shandong, China. Since 2022, we have sold to North America (60.00%), Western Europe (14.00%) and South America (6.00%). There are about 11-50 people in our office.

2. How do we guarantee quality?

Always provide pre-production samples before mass production;

Always carry out final inspection before shipment;

3. What can you buy from us?

Copper, aluminum, die steel, titanium, customized machine parts

4. Why should you buy from us instead of other suppliers?

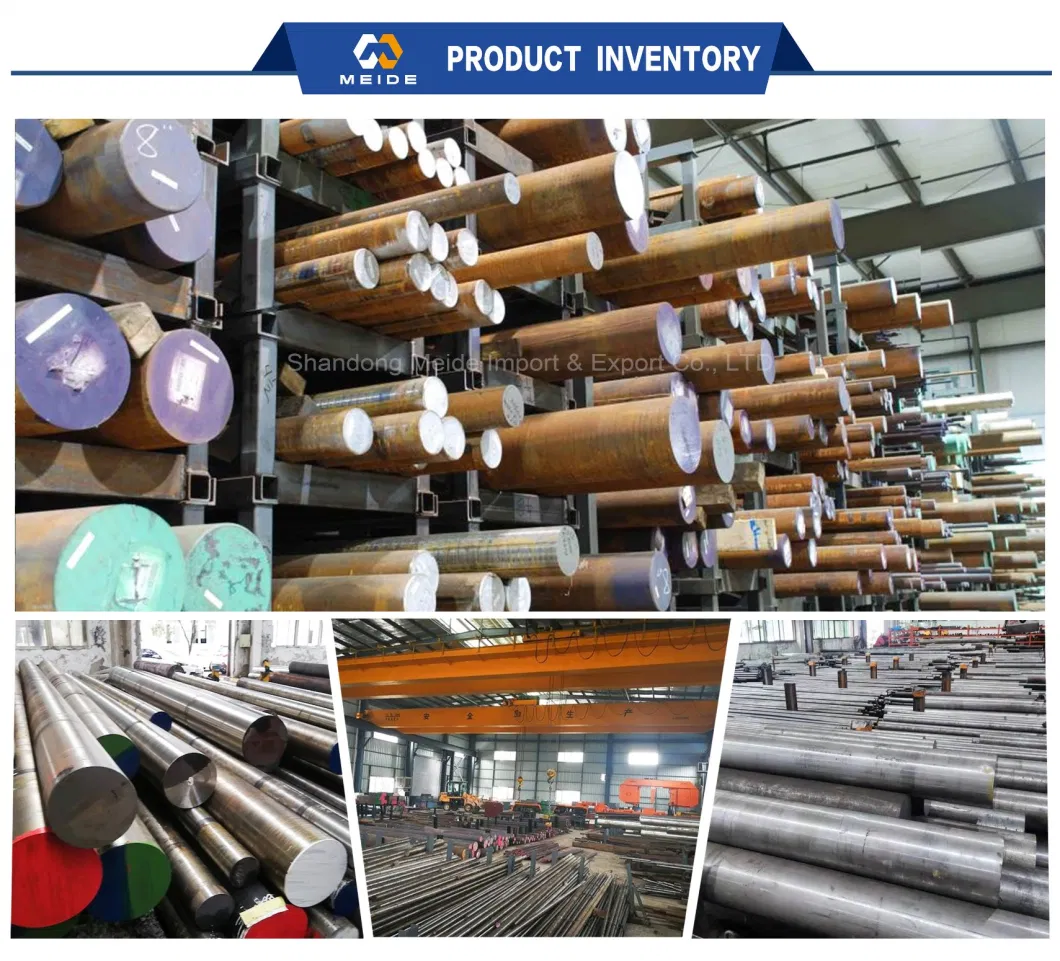

The company has 25 years of production experience. It has advanced precision production equipment, modern large warehouse, 200000 tons of inventory goods and a number of long-term stable cooperative customers.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW

Accepted payment currency: US dollar, Euro, Japanese yen, Canadian dollar, Australian dollar, Hong Kong dollar, British pound, RMB, Swiss franc;

Accepted payment type: T/T, L/C, D/P D/A, PayPal;

Optional ports: Tianjin, Shanghai, Guangzhou;

Spoken: English, Chinese

6. How can we get your price?

A. We need the following information to quote for you:

1). Product Name

2). standard

3). Material grade (chemical composition)

4). dimension

5). amount

6). Special part drawing

Our Contact